Remote maintenance against standstill

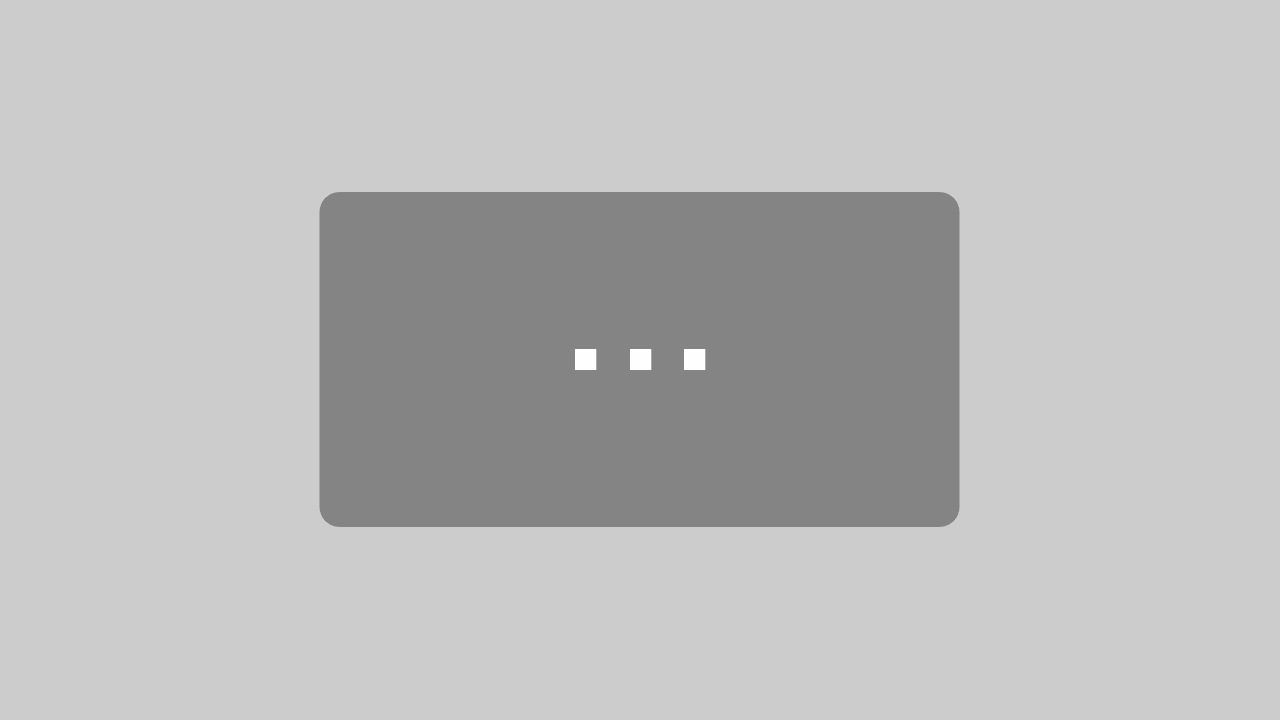

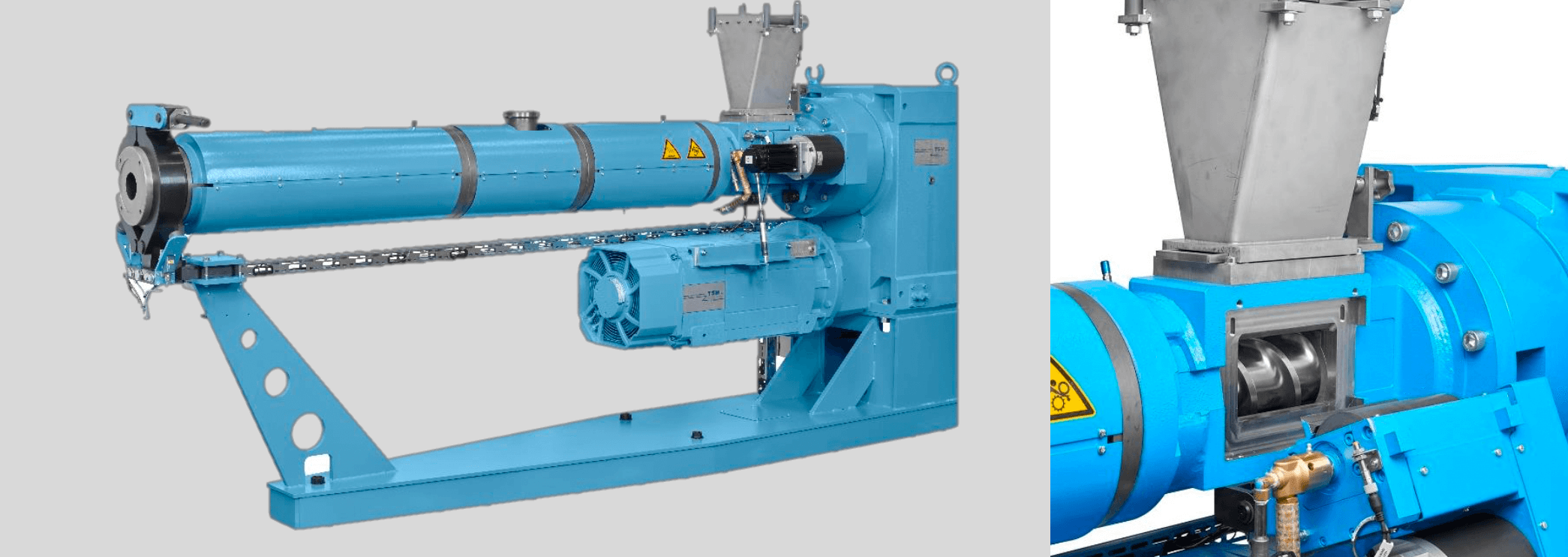

Gerlach stands for quality and has been convincing for more than 40 years with its high performance and high-quality machines for hot-air vulcanization. For our customers, robust and high-performance products finally mean low-maintenance machines that are less susceptible to failures.

Nevertheless, customer service is not only one of our utmost concerns. It is also a further characteristic of comprehensive quality service that Gerlach is well known for.

Therefore, all Gerlach machines are generally prepared for remote maintenance access. Remote access is made via the Siemens SPS configuration software.

Our specialized team of five technicians and three electrical engineers is thus able to access the system parameters remotely and start a fault analysis. Any faults that occur can be localized, the cause investigated, and remedial measures initiated. This reduces machine downtime to a minimum.

Personal coaching for more competence

First, customer operators and technicians receive intensive on-site training from our commissioning team for each of our systems. This has the great advantage that your employees can undertake minor maintenance work on their own. In the event of more far-reaching problems, they can quickly and competently follow the instructions from our technicians. With the expert online support many error messages can be easily corrected. The entire service process is simplified by redundant machine operating concepts, which control individual machines in the overall line concept even from adjacent machines. For urgent on-site operations our service team will be at your side at short notice with support and advice.

In addition, our customers now could use another powerful tool to receive fast and uncomplicated support in the case of malfunctions.

Here Gerlach cooperates with a strong partner: Oculavis.

Global Live Support – Gerlach works with Oculavis

Oculavis Share’s technology enables professional support of our experts via live video transmission. The innovative software solution offers the possibility of problem solving via smartphone, tablet or data glasses – as if our technician were on-site.

Using our support platform, our experts can contact you at the factory and solve the problem together with your technical staff. It is also possible for our support team to combine this support with the remote access via VPN to carry out remote maintenance.

In this way you can send important machine documents and further information on the existing problem situation to our support – help is immediate!

Thanks to the Oculavis Share platform, you can get quick help anywhere in the world – no matter whether you have a question about the settings of our machines or a technical problem.

Fast support thanks to Oculavis – use live remote maintenance with one click

Via our support area, our customers can conveniently register for support via Oculavis by creating a user account. Thus, you will receive fast support for your technical questions about our machines at any time.

Would you like to learn more about Oculavis and our service? Here you will find further information about your advantages and the functionality of Oculavis. Would you like to register as an Oculavis user? Then you can register in our support area!