More than 45 years of experience make Gerlach unique

From the beginning the product is the focus…

Elastic profiles, mostly made of a rubber material, more and more also of silicone, are our daily companions, without us perceiving or even seeing them properly! But they play a key role in many applications: they seal windows and doors in our homes and cars, for example. They ensure that our environment remains comfortable, warm and dry. They are made of natural or synthetic rubber and must be vulcanized to be permanently elastic. Exactly this process is carried out in the vulcanization plants of GERLACH Maschinenbau.

We, Gerlach Maschinenbau GmbH, are the worldwide technology leader in continuous hot air vulcanization. Our customers receive from us tailor-made systems according to their individual ideas – always adapted to the requirements of the final product.

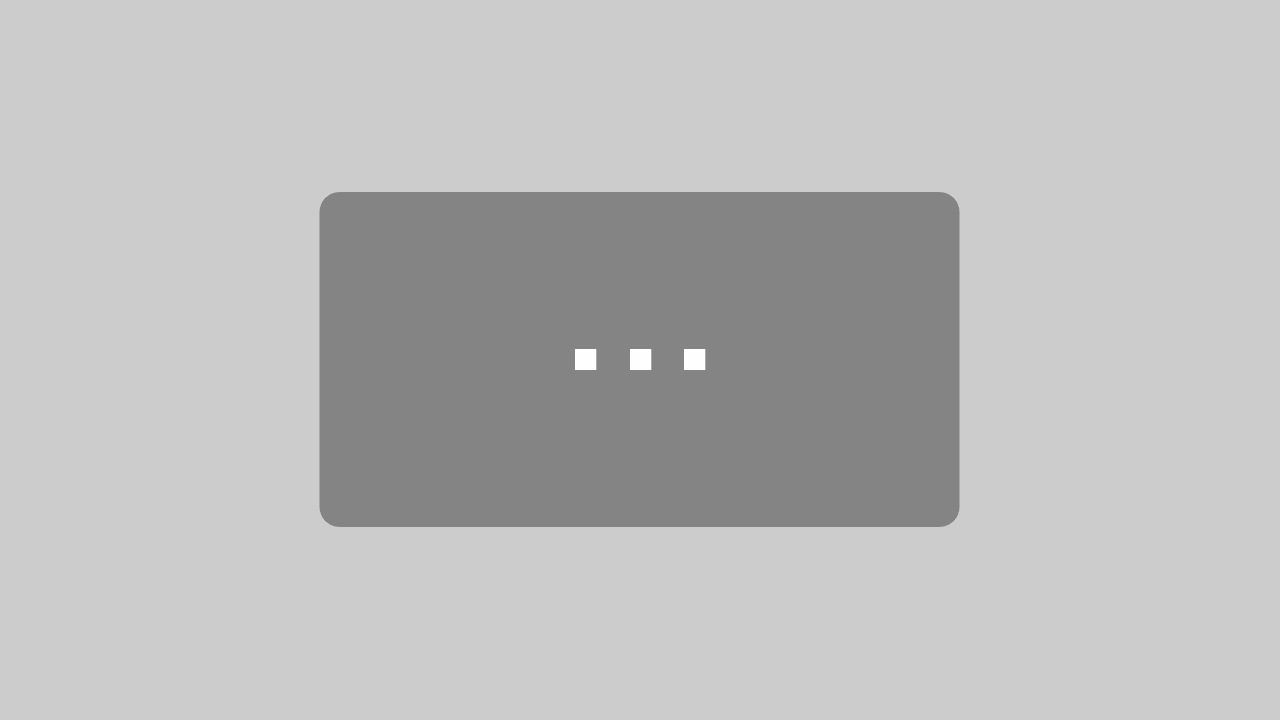

The various vulcanization and drying channels from Gerlach

In addition to hot air, Gerlach also uses other energy sources in the vulcanization and drying ducts with exhaust air cleaning. These include in particular microwave and infrared energy as well as a process-specific combination of these with the hot air. In addition to vulcanization, the cooling of the extrudate and the profile pull-off are an essential part of the extrusion process. Gerlach Maschinenbau also builds and supplies these machines. Depending on the requirements of the customer from the automotive, facade construction, water/waste water treatment, hose production or various other branches of industry, Gerlach’s delivery program includes the individual machine as well as the fully equipped production line for the entire extrusion and vulcanization process at the customer’s site.

The technological “know-how” paired with the excellent mechanical engineering, in execution and quality, have for many years been a guarantee for an efficient and successful rubber vulcanization for our worldwide operating customers.

Our outstanding professional competences are: