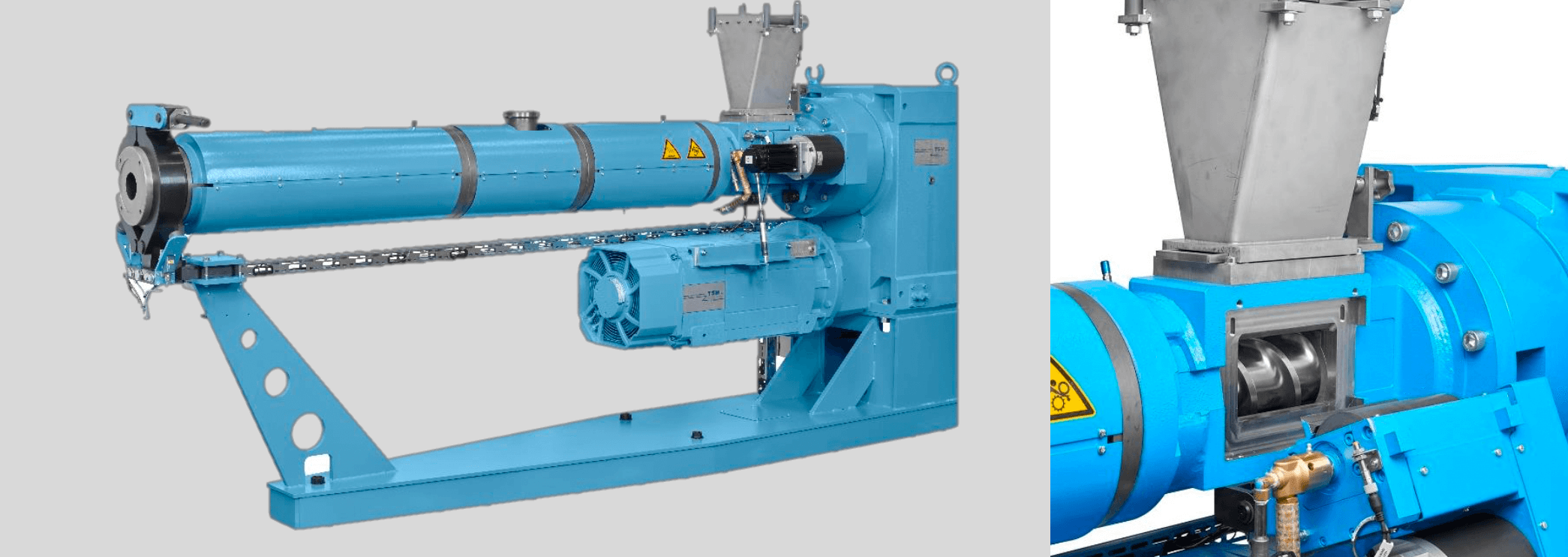

Modular, versatile and “Made in Germany”

GERLACH machines and plants are suitable for the vulcanization of synthetic, natural and silicone rubber. Due to the modular machine design and the use of different treatment stages, excellent product surfaces and properties are achieved at high material throughputs. At the same time, the environmentally friendly GERLACH plants have unprecedented energy efficiency at high production speeds.

Everything from one source

Our production takes place exclusively in our production plant near Düsseldorf. In so doing, we pay attention to many factors, such as to manufacture and mechanical engineering our machines 100% on our own. This is what makes our technology leadership outstanding.

Our extensive machinery covers all necessary production processes, including machining, sheet metal production, painting, cabinet construction and final assembly. In this way, we keep the entire value chain, from the first idea to the finished machine in our hands.