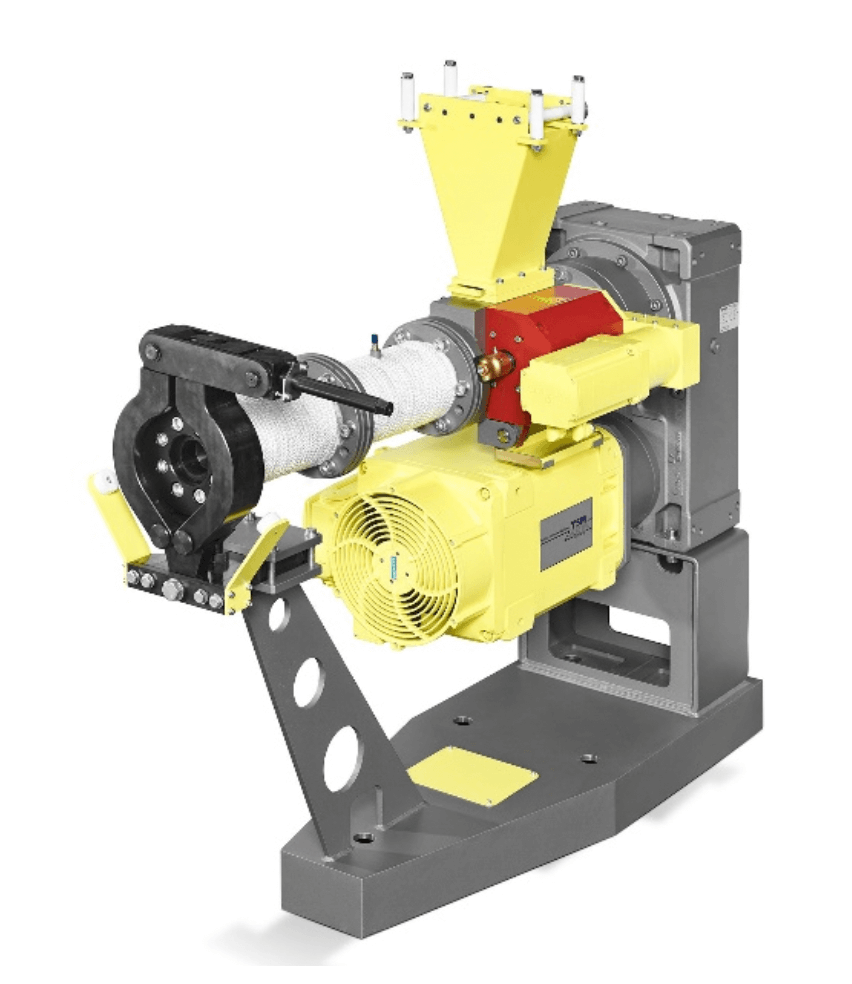

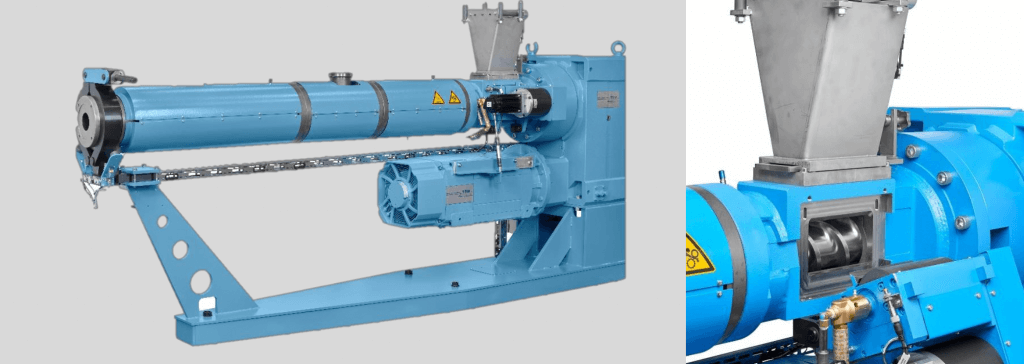

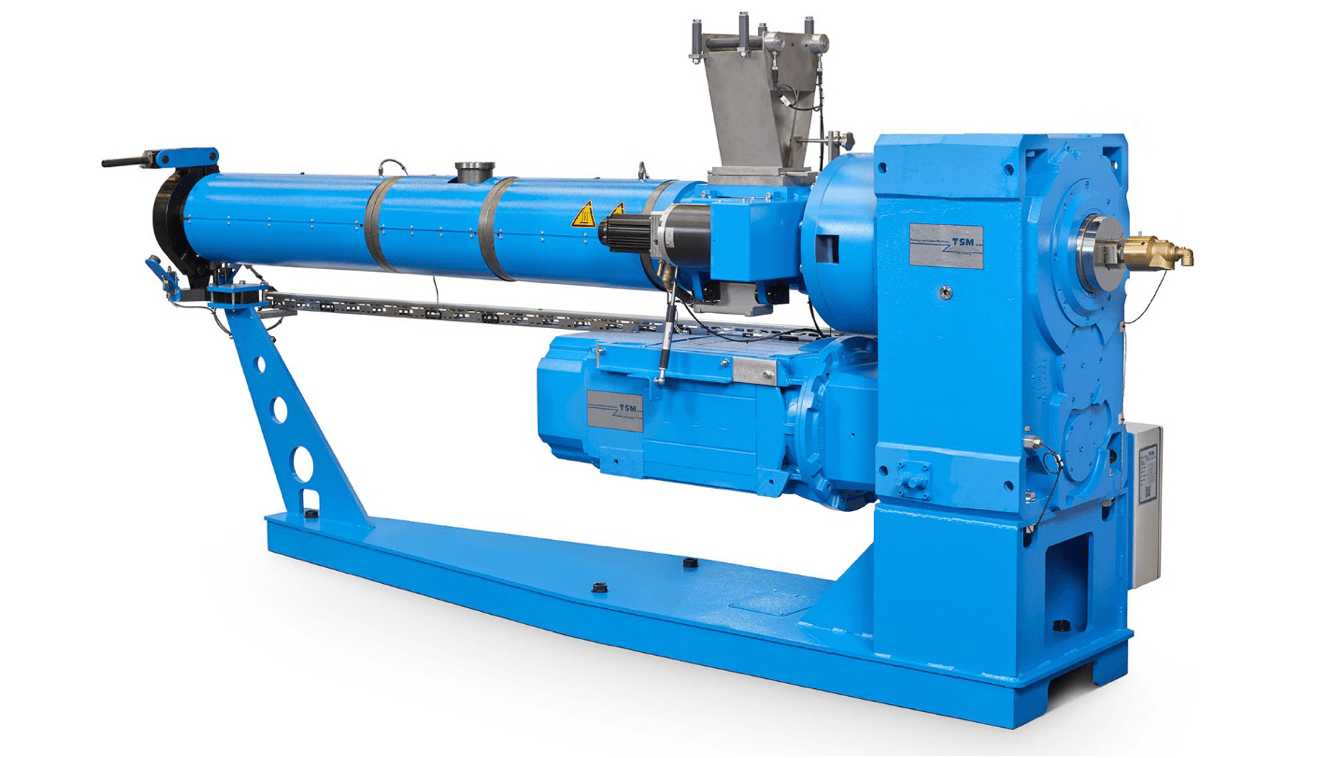

D 35 L/D 15 – D 120 L/D 20

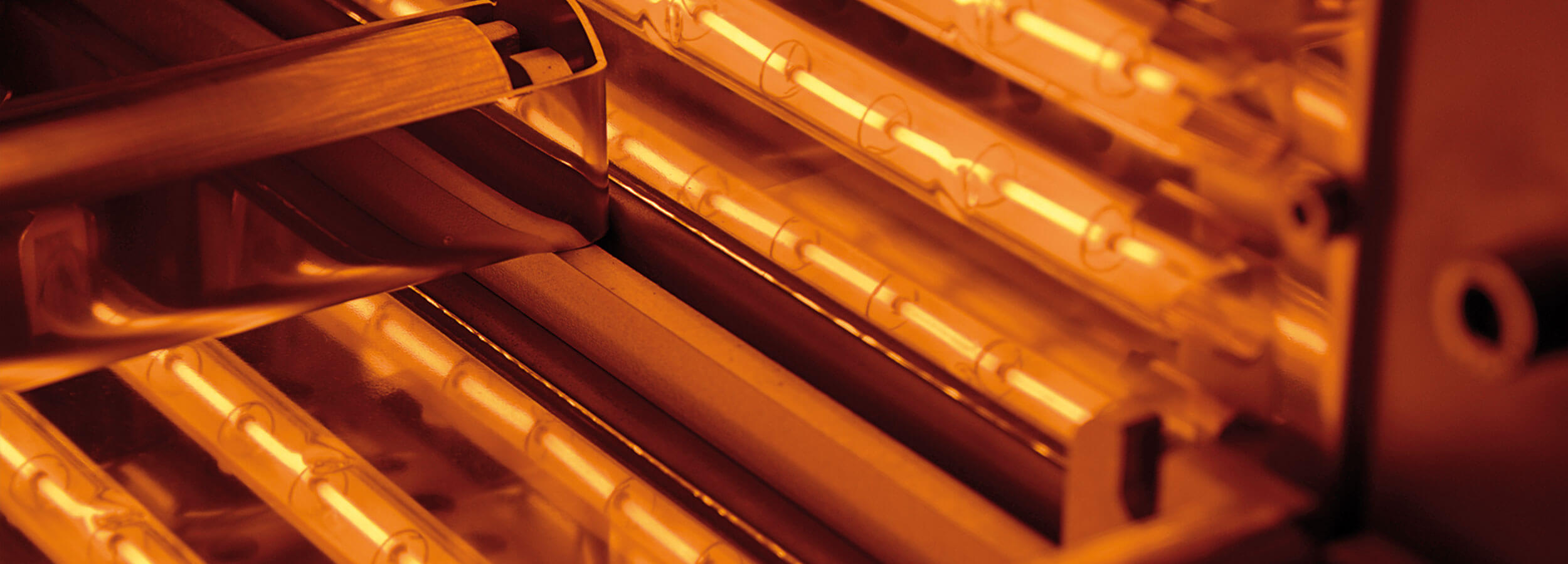

Elastomer extruders are used as part of the continuous extrusion process for processing rubber compounds before the continuous vulcanization process.

For this application, we manufacture compact cold-feed extruders with screw diameters from 35 mm L/D 15 to 120 mm L/D 20.

Depending on the material specification, different surface treatments of screw and barrel can be considered.

Depending on the requirements, the design, size, screw geometry and other parameters can be defined and the extruders can be supplied in standard design, as vacuum extruders, silicone extruders, co-extrusion lines and completed with gear pumps and single or co-extrusion heads if need be.

Our extruders have a separately driven feed roller, the torque or speed is controlled by the PLC control system. The system thus enables screw conveying with absolute precision and with the exact amount of rubber required.

In order to conduct an uncomplicated screw change or for cleaning purposes, most extruders can be moved back and forth electrically.

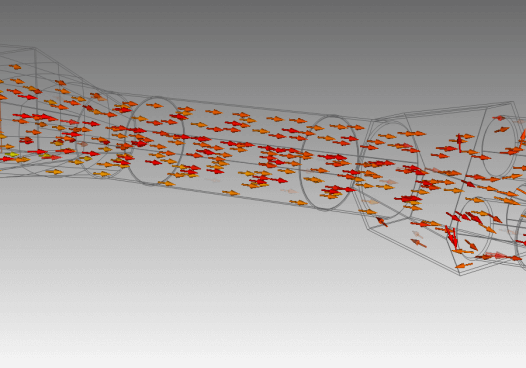

All extruders are equipped with tempered zones, the number of which depends on the diameter of the screw and the length of the extruder. The quantity ranges from one to six zones, including the tempering of the head area.

Our extruders are used in the production of pipes, profiles, cables, hoses, fibres and pipe and profile sheathing.