The UHF-Module 201 offers a new dimension of elastomer crosslinking with microwaves. For the increase of your benefit!

Modular

The UHF-Modul features high flexibility. You can use it wherever a powerful microwave is needed in the vulcanization process.

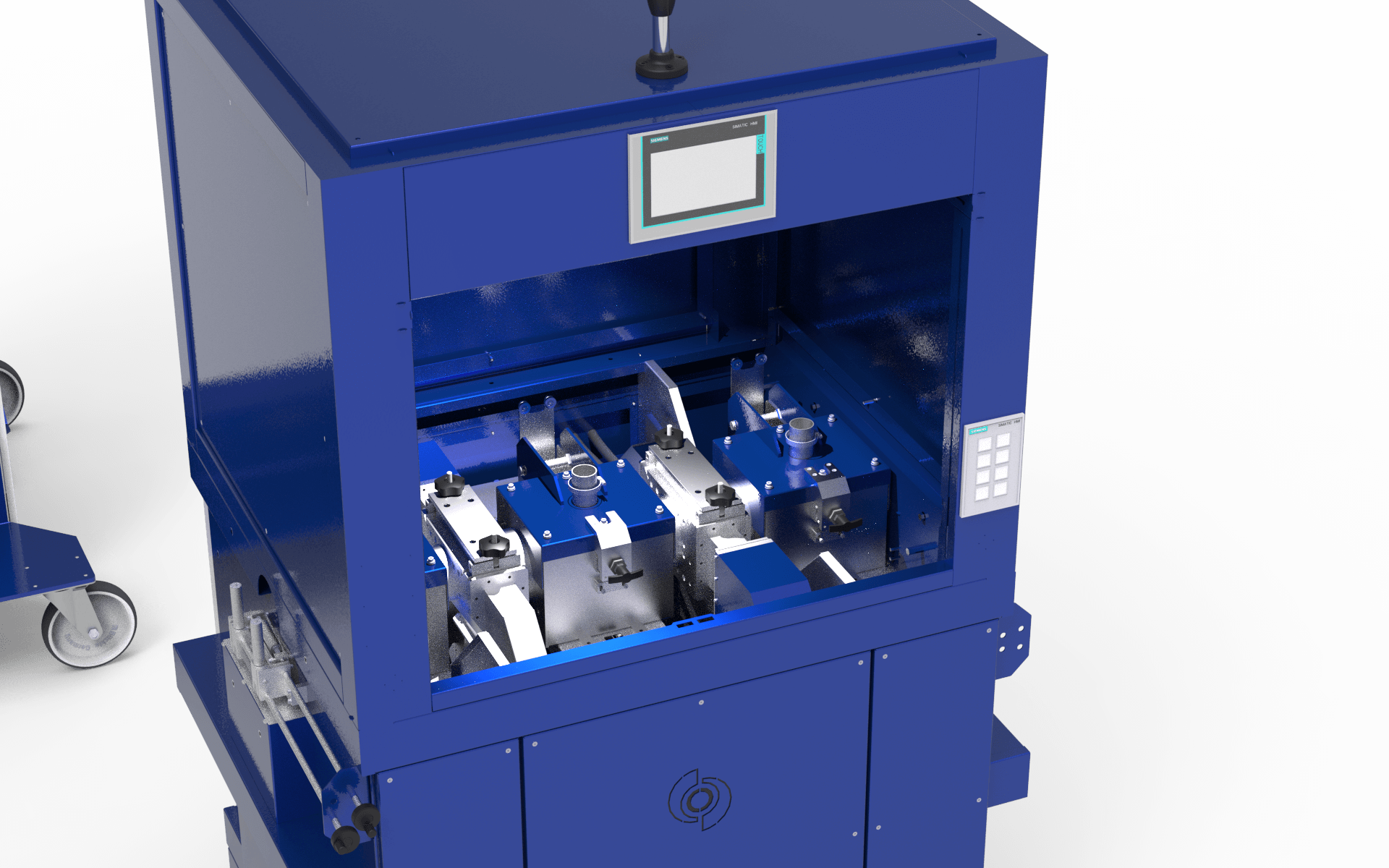

The UHF-Modul is self-sufficient. Due to the compact and mobile design with an integrated switch cabinet, the unit is ready for use at any time. Whether as a single unit or in a network.

Today at the beginning of line 2, tomorrow at the end of the vulcanization line 11 to give the profile the finishing touch, which is no big deal with the mobile version thanks to its modular design and integrated switch cabinet. All you have to do is to disconnect and reconnect the electrical connection – and to move it, of course.

The higher-level communication enables you to unite modules to one large system and to control them centrally via one display.

Each module is subsequently expandable and compatible with all other models of the 200 series.

Efficient

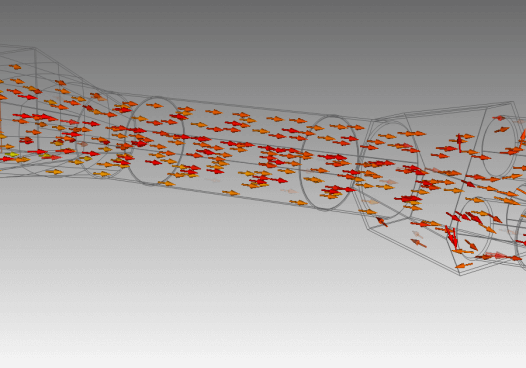

The new guided-wave technology in the UHF module cures the apparently uncurable.

By focusing the microwave radiation, even low polar mixtures can be heated efficiently.

Combine different equipment classes from 500 watts to 6kW and use the amount of energy specifically where your product requires it.

Achieve higher production speeds and react flexibly to product changes without wasting energy.

Unique

This machine series is unique and offers new and flexible application possibilities. Small, compact, individual modules of different energy forms thus become your individual crosslinking unit.

There has never been a more compact design of a microwave unit for crosslinking elastomers. The standard version is equipped with a 2 kW UHF unit with the latest isolator technology and a reflection plane. It requires a footprint of less than 1 m².

Optionally, further functions such as height adjustment, additional reflection planes, etc. can be selected.

An optional thermal imaging camera allows continuous temperature control of the profile during the production process. This makes it possible for the first time to control a microwave via target temperatures and thus to control your product in the best possible way.