Stand-Alone PCT

Exhaust air purification for a cleaner environment!

Gerlach Maschinenbau known as a pioneer and technology leader in hot air vulcanization, once again sets standards and supports the achievement of the CO2 climate targets with innovative machine solutions!

Our solution for existing vulcanization machines without exhaust air purification is the self-sufficient Stand-Alone PCT.

Sustainable energy management and the requirement for air pollution control are increasingly permeating industrial production processes. Older machines present problems in many places because they still emit contaminated and uncleaned process air into the environment. The air contamination that occurs in the rubber vulcanization process results from the combustion of the fossil fuel gas, as well as the use of rubber compounds with different chemical compositions.

In addition to possible odor nuisance, there are various carbon compounds, nitrogen and sulfur oxides in the raw gas verifiable. The self-commitment of the operating company or the legal requirements to comply with limit values, pose a problem for many rubber manufacturers.

Central exhaust gas cleaning systems, which are expensive and require high maintenance level can only be used under certain conditions for older curing channels.

In addition, the energy use concepts are often not profitable and can be adapted to old machines.

Our solution for existing vulcanization machines without exhaust air purification is the self-sufficient Stand-Alone PCT.

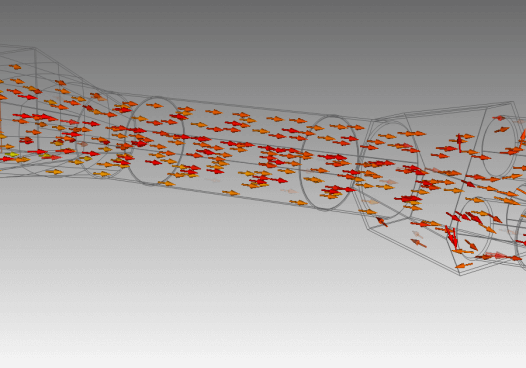

The “Pollution Control Technology” (PCT) well known at Gerlach, has been used successfully for many years and is an integral part of modern hot air vulcanization channels.

PCT technology is used all over the world and has been helping our customers to comply with exhaust emission limits for many years. In the next expansion stage, the PCT was further developed and designed as a self-sufficient exhaust air cleaning machine for retrofitting on old machines.

Complex piping systems and, if necessary, the purchase of a much more expensive central exhaust air purification can be omitted by using the stand-alone PCT.

The energy required for exhaust gas cleaning is not lost but is largely reused in the vulcanization process. In addition to air pollution control and the contribution to achieving the climate targets, there are further additional energy-saving effects due to the active principle of the circulating air process.

Furthermore, this solution offers to our customers energy recovery for subsequent heating or cooling processes.

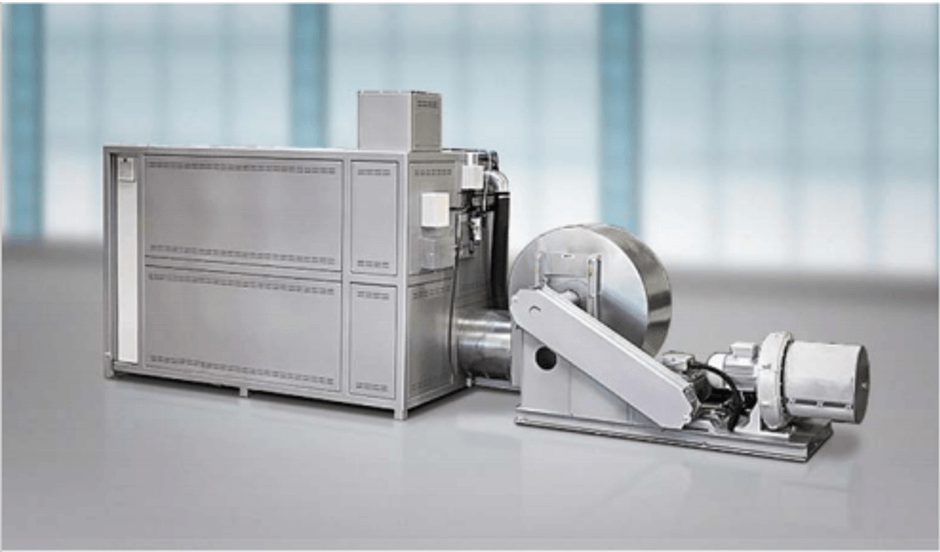

Currently, the Stand-Alone PCT is available in two designs. In variant A, the fans are placed on the floor next to the stand-alone PCT (Fig. 1). In variant B, the fans are mounted on top of the PCT housing to save space.

As is natural for a stand-alone system, the Stand-Alone PCT comes with its own control and touch display.

A connection to an existing control system is possible with restrictions after prior clarification.

Machine highlights

- Fan technology as floor or stage mounted version possible

- Energy recovery in air recirculation mode possible

- Machine operation via touch panel

- Compact and self-sustaining machine design