Consulting & Planning

Mixtures of materials

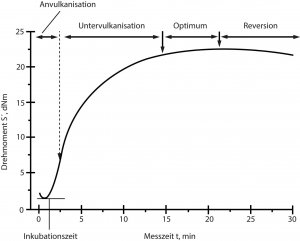

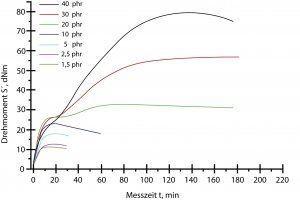

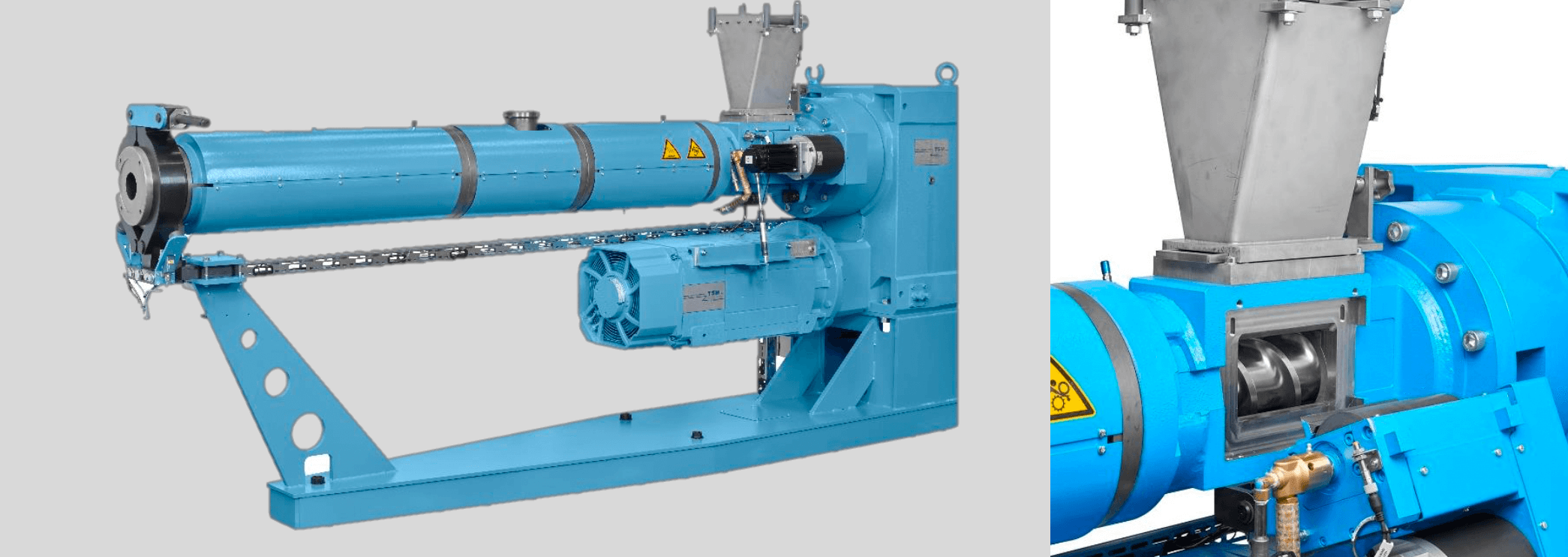

In addition to plant equipment, the selection of the right mixtures of materials plays a major role in the quality of the final product. By working closely with different manufacturers, we are able to test your mixtures on our extruder plants and subsequently perform common optimisation. Finally we will advise you on the vulcanization process for your production line and provide you with detailed information about the surface structure, the quality and the calculated production time of the final product.

Process technologies

The process technology is one of our most important core components and reason for the high efficiency of the GERLACH industrial engineering. Through close cooperation with scientific institutions, we are always working on further optimisation and refinement of the mode of operation. In addition, we provide you with support with the design of your vulcanization line with our many years of experience. With the aid of our partners, we configure the industrial engineering components to optimally adapt to your application.

Financing

The acquisition of machinery is always an investment that must be calculated and prepared. Particularly for special-purpose machines, many financial institutions have difficulties in assessing the value and classification of the assets. For this reason, we have been working closely with well-known financing service providers for many years and we are happy to arrange suitable contacts. No matter whether it is leasing, financing or price-sharing – we will find a tailor-made solution together with the appropriate credit institutions.