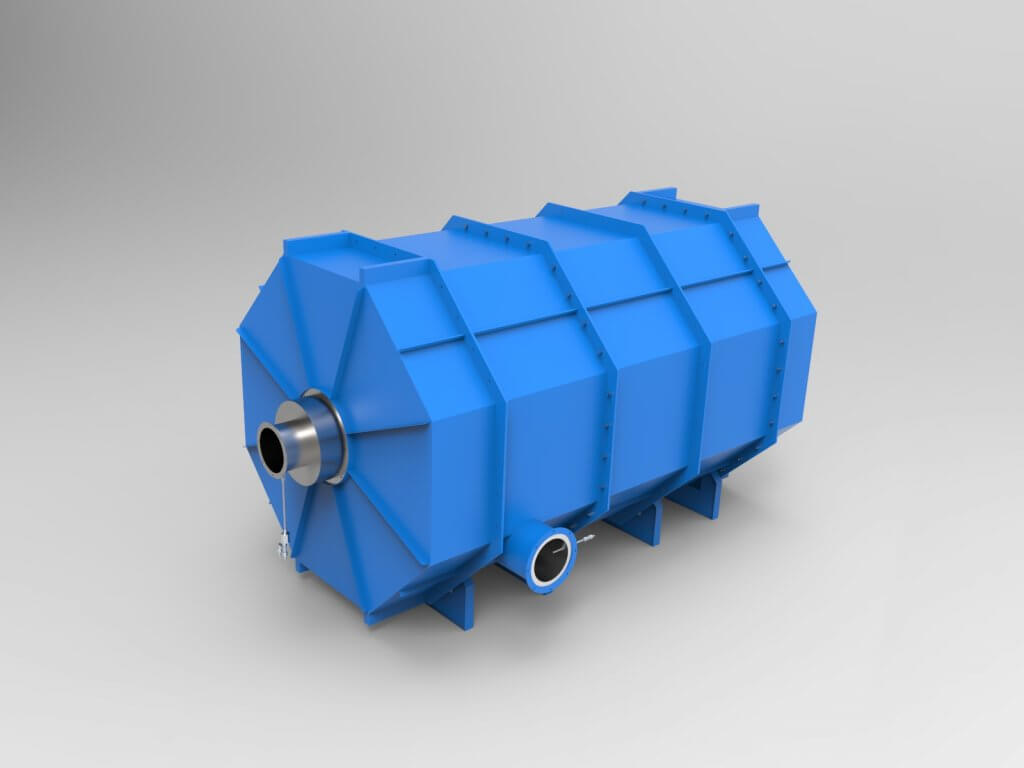

Combustion Chamber

OCTOtherm BK 400

Improve your energy efficiency

and reduce your gas consumption by 50 %

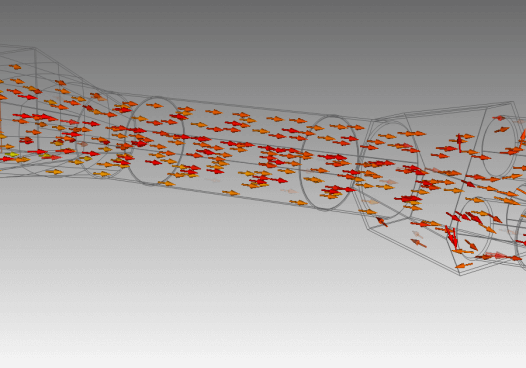

The OCTOtherm BK 400 is a new, central heating system for vulcanization and drying channels. In addition to the task of providing hot air into the vulcanization channel, the combustion chamber also performs the task of exhaust air purification. The maximum energy efficiency of the vulcanization channel, in combination with the BK 400, is ensured by the circulating air principle.

Compared to conventional hot air channel, which are operated with burner outputs of 200 kW and more, the BK 400 uses far lower power, according to which an energy saving potential of 50% can be achieved.

The optimal thermodynamic design of the chamber in combination with the preselected operating mode allows a very fast heating of the entire circulating air volume. In this way, heating costs and heating times can already be reduced in the heating phase.

The BK 400 reaches chamber temperatures of up to 900°C and is able to clean an air volume of up to 550 Bm³/h. At the same time, a maximum channel temperature of 340°C is provided.

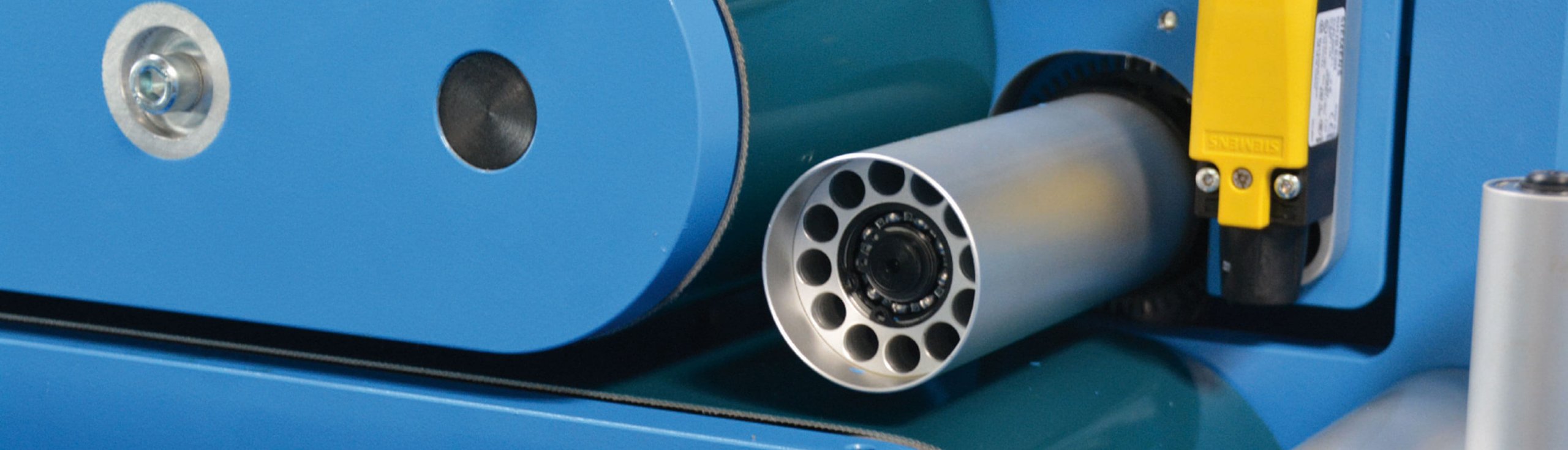

The double-walled 200 mm thick and sustainable, since mineral, special insulation of the chamber, ensures extremely good thermal insulation of the outer surfaces. The special design of the air duct optimally heats the supplied fresh air before it is fed into the actual combustion chamber. Due to its design, the chamber is easily accessible and therefore very inspection and service friendly. The OCTOtherm BK 400 can be combined with Gerlach hot air vulcanization channels and is suitable for duct lengths of up to 24 m. The OCTOtherm BK 400 can be mounted either behind the vulcanization channel or on a platform above it.

The scope of delivery includes a modern burner control, fresh air supply and the required electrical power supply. The OCTOtherm BK 400 is operated via the operator panel of the hot air channel or via a self-sufficient control.

Machine highlights

- Hot air supply of the vulcanization channel up to 340 °C

- Cleaning of contaminated process air

- Easy to maintain

- Compact design

- Self-sufficient or integrated combustion chamber operation

- Energy savings of 50 % compared to conventional systems