Modular overall system

Traditionally GERLACH plants are used for the production of sealing profiles made of synthetic rubber in the automotive, industrial, building construction and civil engineering industries.

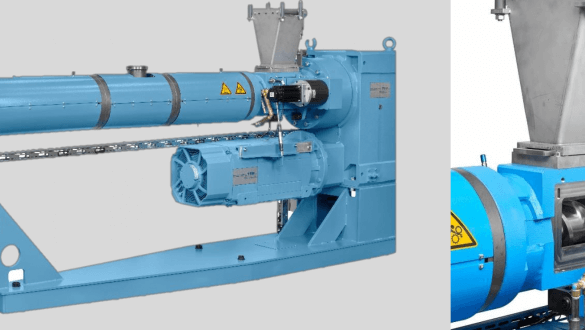

Extruder

Extruder Gerlach’s product range includes cold-fed compact extruders, which are built according to the requirements of our customers. Our extruders process strip or granulate mixtures and can be supplied with various equipment variants.

Pre-shock equipment

Fast profile pre-crosslinking in a short space. We offer gas and electric machines with different heating intensities as well as modulation possibilities. Infra-red, gas-ceramic, flow burners as well as adapted hot-air pre-shocks. The machines are configurable for single or multiple extrusion as well as mobile stand-alone machines.

Microwave channels

Our combined high-performance shock channels unite the performance of all individual modules. Thanks to modular configurations, the units PreShock, shock module, microwave zone and hot air zone are combined in an energy-saving mode of operation. Through the integration of the optionally available exhaust air purification (PCT), the Gerlach SHF machine is an environmentally friendly and powerful overall concept.

Cooling channels

Noise-reduced effective profile cooling by spray, surge or immersion cooling for flexible and rigid products. Modular 3 m zone construction, equipped with transport roller conveyors, with or without blow-off, as well as mobile cooling ducts with and without product conveyor belt supplement our product range.

Supplementary equipment

Supplementary equipment In addition to hot-air vulcanization plants, Gerlach Maschinenbau GmbH also offers supplementary machines for rubber and vulcanization equipment.

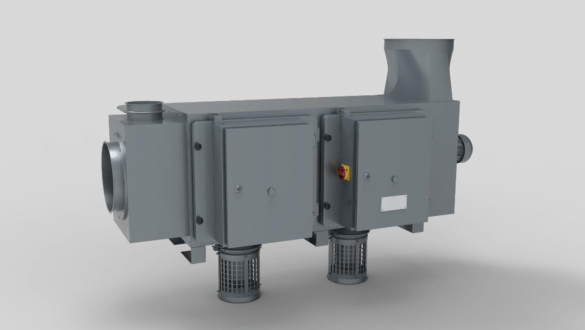

Exhaust air purification

Vapors, odors and pollutants produced during vulcanization can have a significant impact on the environment and health and must therefore be neutralized and disposed of. Gerlach offers compact solutions that are already integrated into the machines and self-sufficient exhaust air purification systems that can be connected to old machines or third-party machines, for example.

Shock channels

In particular to increase efficiency, modular, compact 3 m shock channels with driven rollers as well as with and without an inlet conveyor belt are used. By using gas heating, shock temperatures of up to 550 °C can be generated. The energy concept takes into account the use of process air in the recirculation process. The accelerated hot air flowing turbulently in the channel generates the fastest possible heat transfer.

Hot air channels

Our machine series of the type HLK can be used as holding section, drying or vulcanising machine. Our modular concept offers the system configuration according to your wishes. Whether in fresh air or environmentally friendly air recirculation with exhaust air purification, we offer the right configuration for every requirement.

Experts

Experts In our Experts section, we present special applications, machines and applications in the field of research & development. The Gerlach Expert System GXPS combines individual machines and aggregates in the production of elastomer profiles to the complex unit of a complete production line