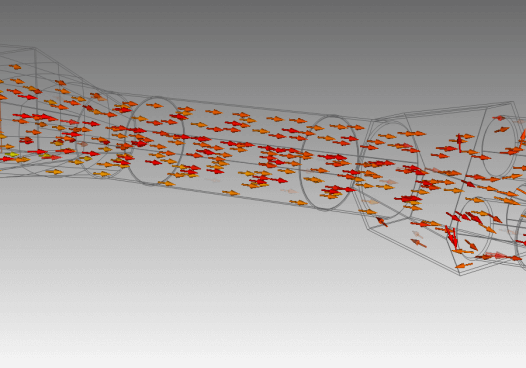

SHF 145

The SHF 145 shock canal is especially suited for profile production in the automotive, industrial, and civil engineering sectors. In addition to the material EPDM, sulphur-crosslinked NBR and SBR rubbers can also be processed. With the use of turbulent hot air combined with up to 24 KW microwave power, large-volume profiles can also be easily processed. The fresh air system offers a good modulation possibility of the temperature ranges.

Machine highlights

- Effective machine lengths 6 – 18 m

- Natural gas heating LNG / LPG- according to Euronorm

- Production speed up to 60 m / min

- Shock temperatures up to 500 °C

- Microwave power up to 24 kW

- High speed hot air zone

- Separate roller and belt drive

- Integrated exhaust air purification (PCT), type SHF 147

- Energy-efficient mode of operation