The Hot Air Module 203

Innovative heating delivers outstanding energy efficiency

Generate 500°C hot air with 2 kW power

At Gerlach Maschinenbau, we were already thinking about how to optimize plant performance and reduce energy consumption long before the current energy situation. The new innovative heating combined with the thermodynamic know-how results in an impressive machine solution.

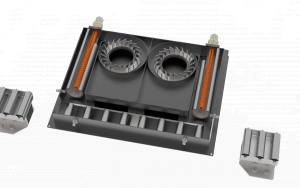

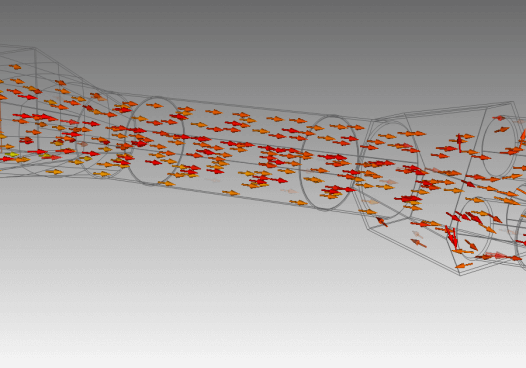

One result of these developments is the novel, electrically heated hot air module 203 with its extremely energy-saving circulating air system for vulcanizing, shocking and heating.

There has never been a more energy-efficient air-shock unit for cross-linking elastomers or other tasks that require the heating of surfaces. In the standard version equipped with 2 heating elements with just 1 kW power each, temperatures of more than 450°C can be reached.

Validations in the field provide impressive results, according to which, for example, a surface heating of a rubber profile of over 200°C can be achieved within 4 seconds.

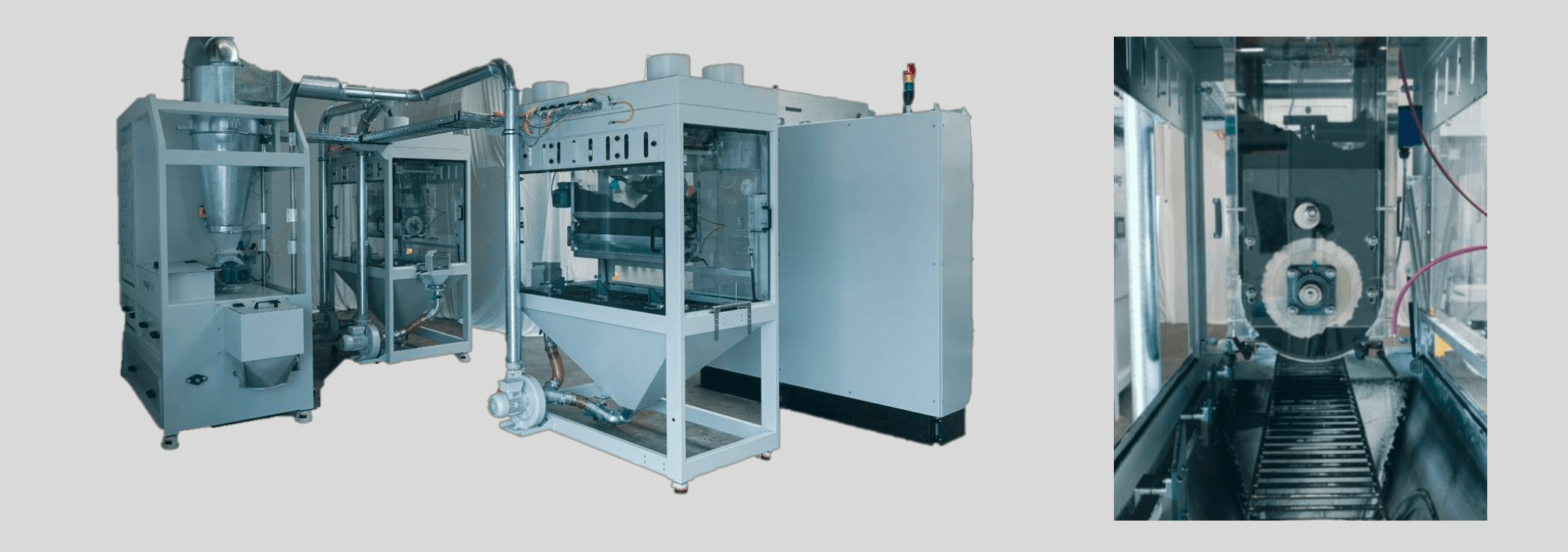

The Hot air module 203

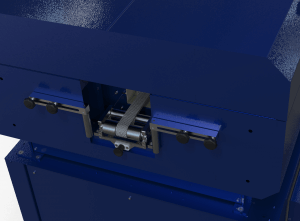

The hot air module 203 with its new, unique hot air technology is characterized by high flexibility and can be used where a powerful hot air system is required. The range of applications is versatile and not limited to elastomer processing industries. It can also be used in the plastics sector, for example for rapid preheating of plastic parts prior to further processing. The hot-air module is self-sufficient and, thanks to its compact and mobile design with integrated control cabinet, ready for use at any time, both as a stand-alone unit and in a network.

The higher-level communication makes it possible to combine modules into a large system and control them centrally via one display. Each module is subsequently expandable and compatible with all other models of the 200 series.