Caterpillar BA 400

New belt puller for profiles, hoses, pipes and cables

The complete solution that leaves nothing to be desired!

The GERLACH caterpillar puller BA 400.

With the type BA 400 we present a mobile and flexible belt and caterpillar puller with synchronous servo technology, which ensures extremely high synchronization in the entire speed range.

- Belt contact length 400 mm 15.75”

- Product height 5 – 60 mm 0.2 – 2.36 “

- Product width 5 – 140 mm 0.2 – 5.5”

- Height to centerline ≥ 1.000 mm ≥ 39.4”

- Belt width 150 mm 5.9”

- Speed range 0 – 60 m/min. 0 – 200 ft/min.

- Pull-off force up to 2000 N up to 450 Pounds force (lb.)

- Machine dimensions (LxWxH) 950 x 580 x 1400mm ~ 3 x 2 x 4.5 ft.

SAFETY FIRST

Who does not know it? Safety devices on machines often interfere with the ease of operation. Belt pullers in particular are often equipped with safety devices that make it difficult for the operator to thread the material. True to the motto “necessity is the mother of invention”, machine operators sometimes make do by dismantling or bridging safety devices. All of this leads to unacceptable safety risks.

This safety and ease of use were central elements during development. That is why our caterpillar puller was developed around the safety concept. Thus, the belt puller offers a new type of security concept that guarantees the highest level of security and does not restrict operation.

The automatic pressure monitoring offers particular ease of use. After specifying the speed setpoint and pressing the “green button” (fig. 1), the puller starts automatically; further steps are not required by the operator.

Fig. 1

A characteristic feature of the Gerlach caterpillar puller is the automatic pressure monitoring system. This automatic pressure monitoring assures that the product is not compressed in an uncontrolled manner, which can lead to permanent material damage and deformation of the product. As soon as the required friction between the upper and lower belt and the product has been achieved, the puller starts with a minimally required contact pressure that is continuously monitored.

In the standard version, extrudate heights of up to 60mm can be processed; alternative material dimensions can, of course, be realized according to customer requirements.

Permanent material stress, extrudate deformation and shrinkage due to high tensile forces are a well-known problem in quality assurance. The Gerlach puller BA 400 offers a special feature to counteract this problem. The machine is equipped with a “force control” function. With “force control” you can permanently measure the pull-off force and regulate the pull-off speed.

In continuous extrusion processes, ensuring material continuation and removal is an essential component in production lines.

Of course, the function of continuous material movement is integrated into many machines. However, it is not possible without a specialist who exclusively ensures this task! This refers to the caterpillar puller!

The requirements on the machine result from the production process, the product quality and the interaction between man and machine, as well as the demand to consider the highest safety standards.

The Gerlach belt puller sets new standards in the continuous pulling of profiles, hoses, pipes, or cables.

Additional features

In addition to the mentioned highlights, the puller offers additional features such as:

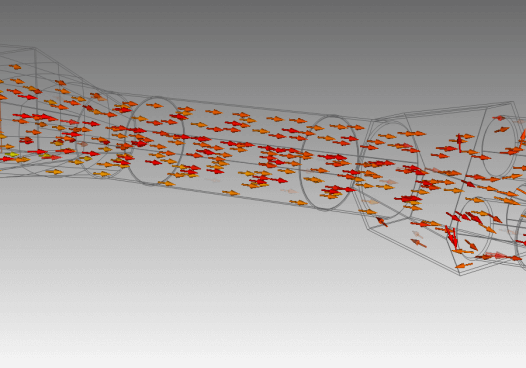

- Mobile machine design with retractable adjustable feet (fig. 2)

- Speed control via an integrated loop control

- Left-to-right and right-to-left operation

- Contact protection guard

- Integrated PLC line control and recipe management

- Touch-screen HMI

- Automatic slip compensation and loop compensation

- Automatic power connection rewind

- fault diagnosis

- acoustic and visual machine status signal

- Switch cabinet climatization unit as an option

Fig. 2

Product video