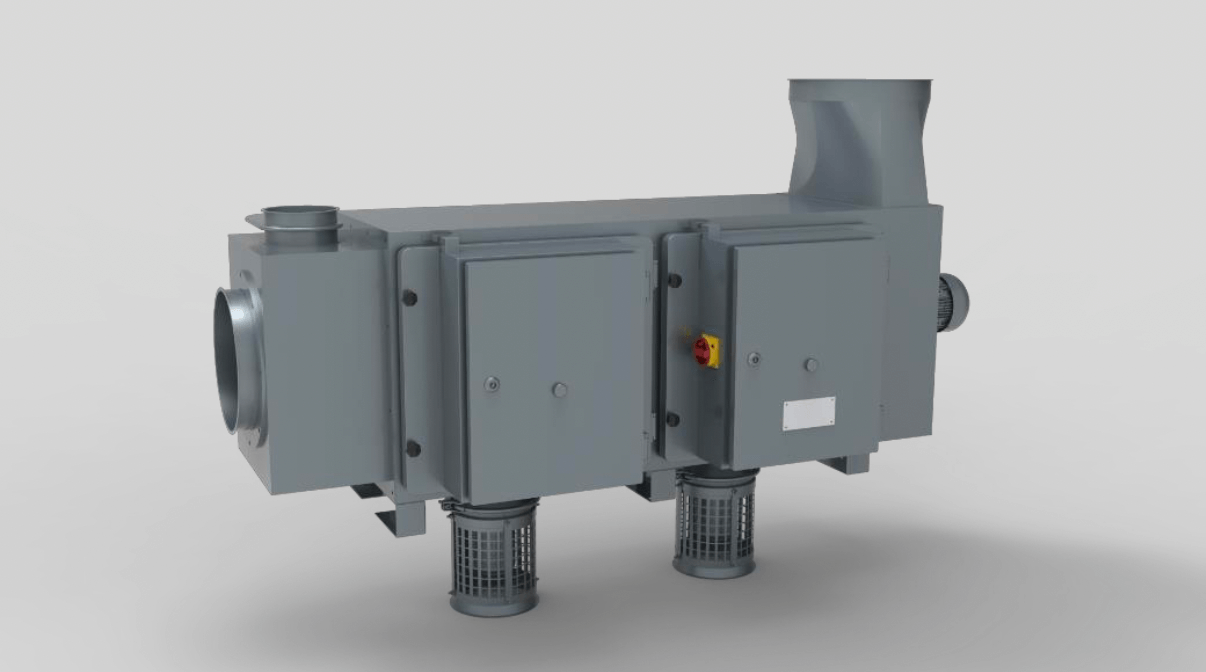

Electrostatic precipitator 450

The electrostatic precipitator 450 for exhaust gas aftertreatment / cleaning of vulcanization vapors is compact, modular and extremely energy-saving.

Vapors, odors and pollutants produced during vulcanization can have a significant impact on the environment and health and must therefore be neutralized and disposed of.

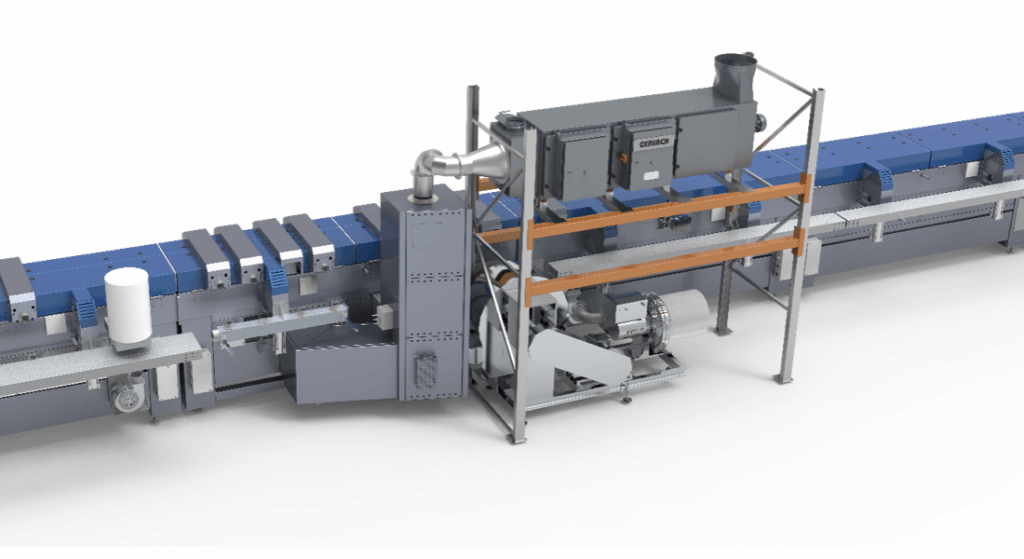

Gerlach offers compact solutions that are already integrated into the machines and self-sufficient exhaust air purification systems that can be connected to old machines or third-party machines, for example.

The latest generation of exhaust air purification systems includes the energy-efficient electrostatic precipitator, in which the pollutants, odors and particles contained in the exhaust air are treated and separated in a high-voltage electric field.

The electrostatic precipitator consists of a modular system and can be expanded modularly depending on the requirements. Depending on the amount of air to be cleaned and contamination, filter stages can be variably supplemented. The unit works independently of your vulcanization system and can thus be operated not only on Gerlach systems, but on almost all hot air and microwave units.

Mode of operation

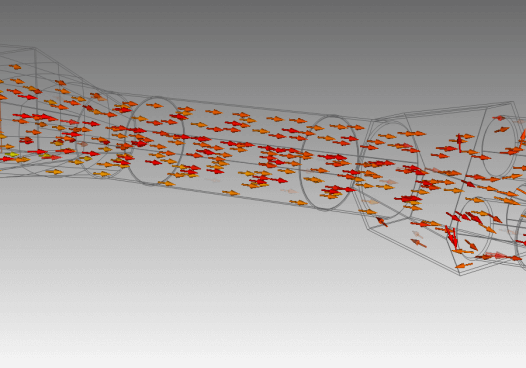

The electrostatic precipitator takes the exhaust gases from the vulcanization system and cools them down to a temperature of about 80°C. In the individual filter stages is an electrostatic high-voltage field that filters out the suspended solids from the air. The optionally available filter stage with activated carbon also neutralizes odor-intensive substances.

Each filter stage is equipped with an individually lockable door, which allows quick inspection and easy replacement of the filter elements from the front.

An average filter system, including the fan power, consumes less than 5kW/h. and is therefore significantly more energy-saving than the usual thermal exhaust gas aftertreatment on the market.

By using the electrostatic precipitator, you not only save energy. Depending on the particle size, the separation capacity is >99%.

This is what active environmental protection and sustainability in rubber processing looks like today!